Introduction

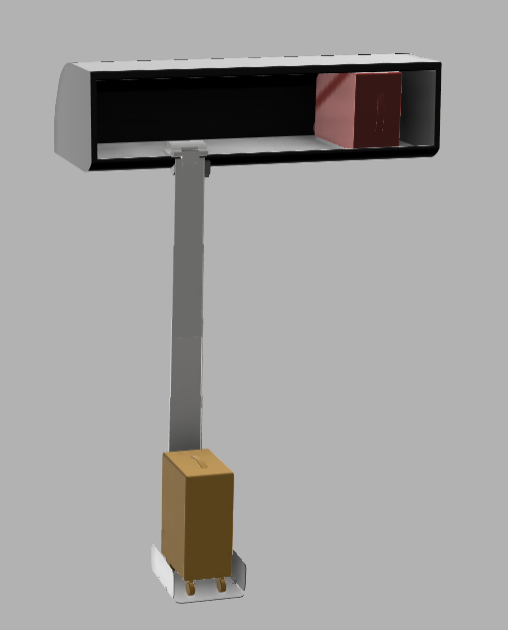

This product was designed during a one day CADathon sprint hosted by ASME x Boeing where my team won 1st place. Following the design prompt: design a solution meant to be a consumer product for an individual to buy, and only stows luggage for one passenger, my team created a portable lift that attaches to the overhead stow bins to lift luggage with minimal user involvement.

Problem statement: Current air travel issues that passengers face when it comes to storing their luggage in the overhead bins such as physical strain, boarding delays, and accessibility issues.

Constraints

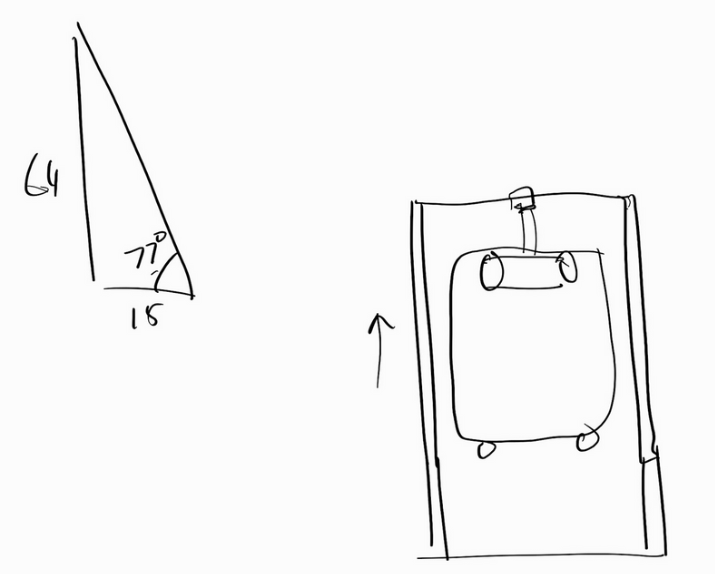

- Lifts luggage (15-35 lbs) up to 64 inches.

- Accommodates "Personal Item" to "Carry-on Item" sizes.

- Fits in aisles

- Ensures safe, easy, and fast operation (faster than an able-bodied person).

- Capable of lifting and lowering luggage.

- Must be an add-on design without modifying the aircraft's structure.

- Accommodates "Personal Item" to "Carry-on Item" sizes.

- Fits in aisles

- Ensures safe, easy, and fast operation (faster than an able-bodied person).

- Capable of lifting and lowering luggage.

- Must be an add-on design without modifying the aircraft's structure.

Features

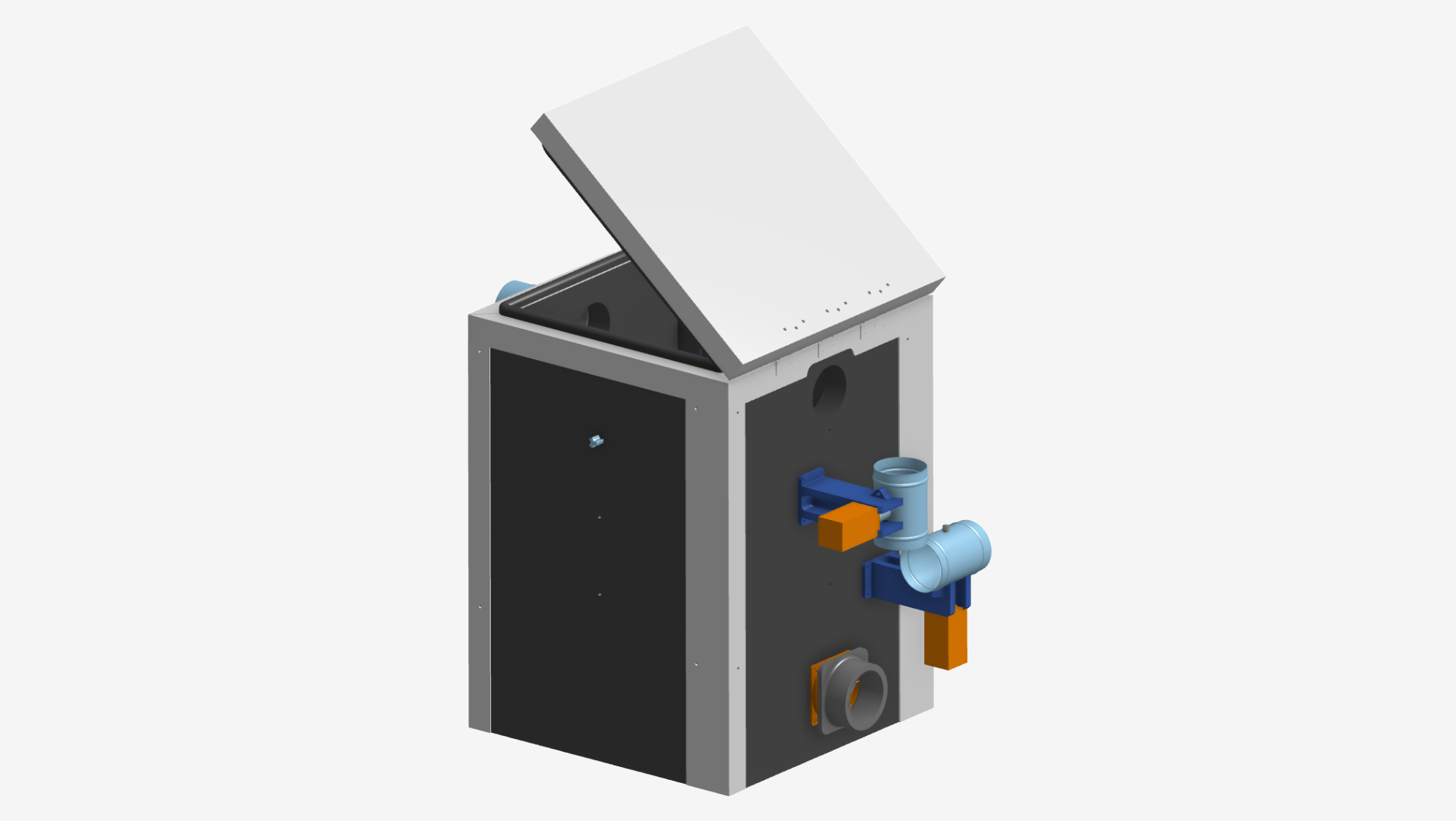

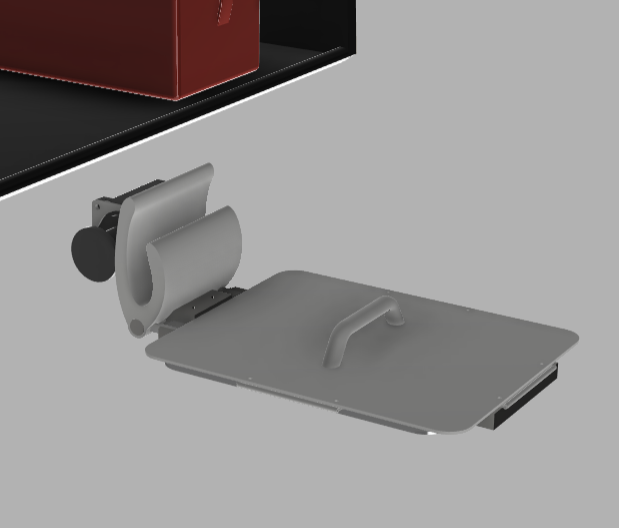

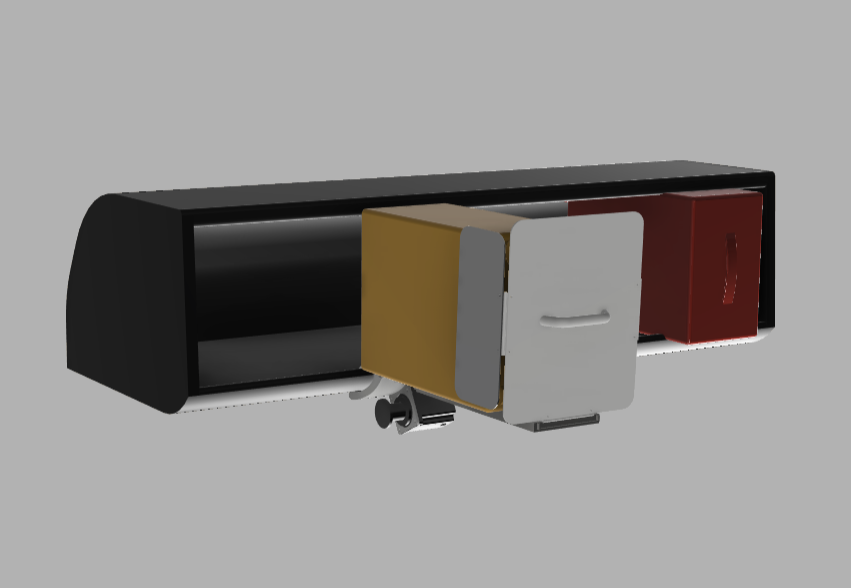

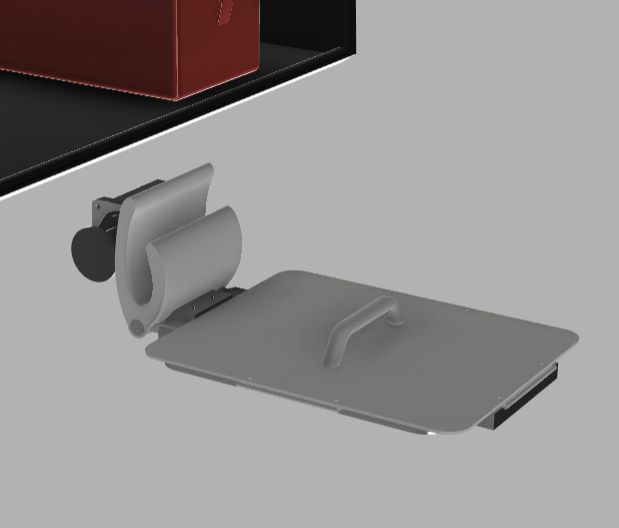

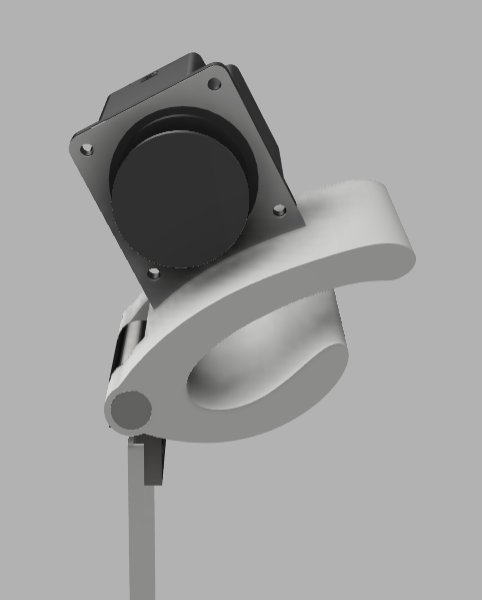

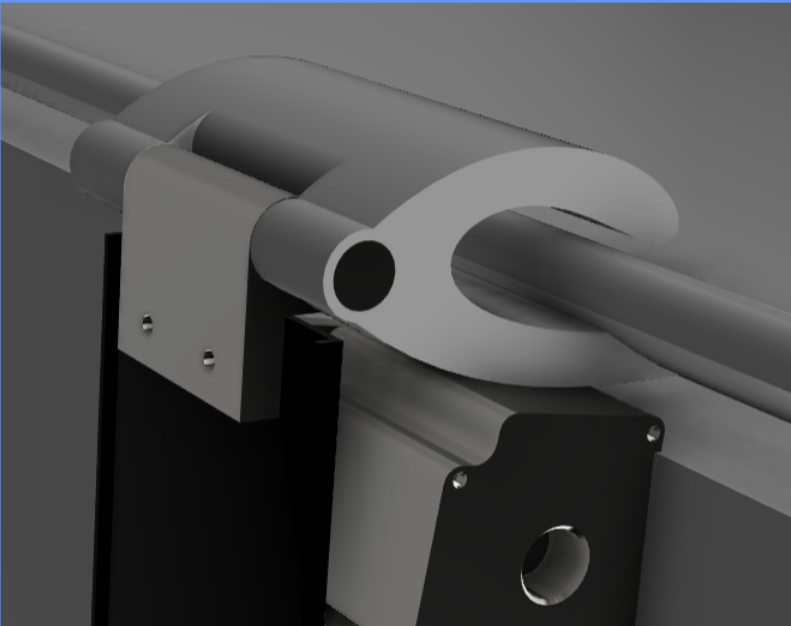

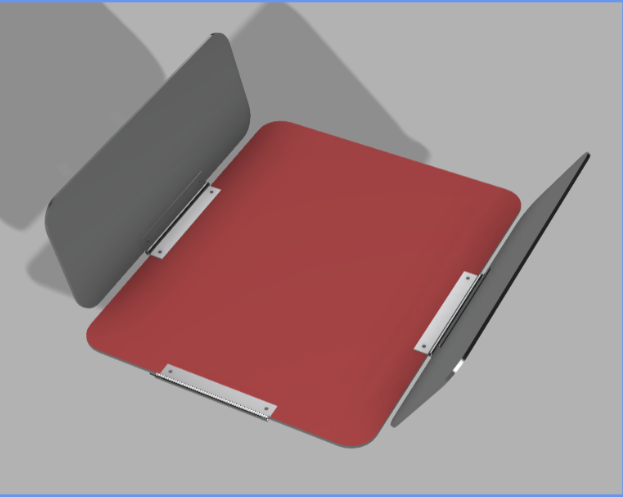

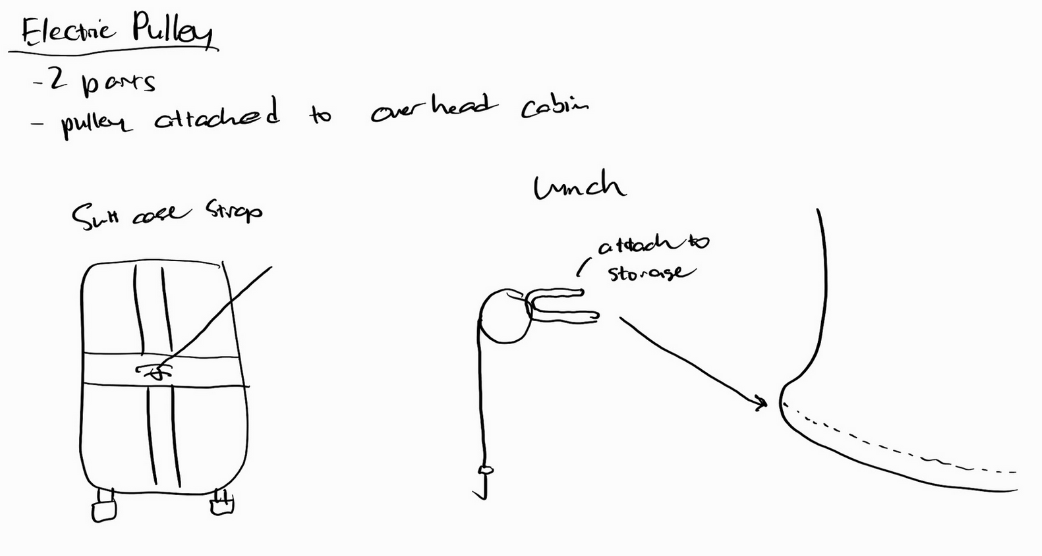

We implemented several features, including a clamp, a Nema 34 motor with 870 in.-oz torque for the winch, a stable strap, guide flaps, slip-resistant covers, and a hinge. The clamp ensures an easy friction fit onto the lip of the overhead bin and is connected to a hinge that adjusts the device angle for different seat heights and aisle levels. The heavy-duty motor efficiently lifts the maximum load to the bin without adding excessive weight. A thick nylon strap provides additional support and stability, reducing sway. Guide flaps on the footplate sides accommodate various luggage sizes and prevent bags from falling off during lifting. A rubber cover on the footplate base minimizes the risk of luggage slipping. Finally, the device folds into a compact shape for easy stowing in overhead bins or under seats.

Compact and portable design

Motorized lift

Clamp for overhead bins

Rubber bottom

Guide flaps

Design Process

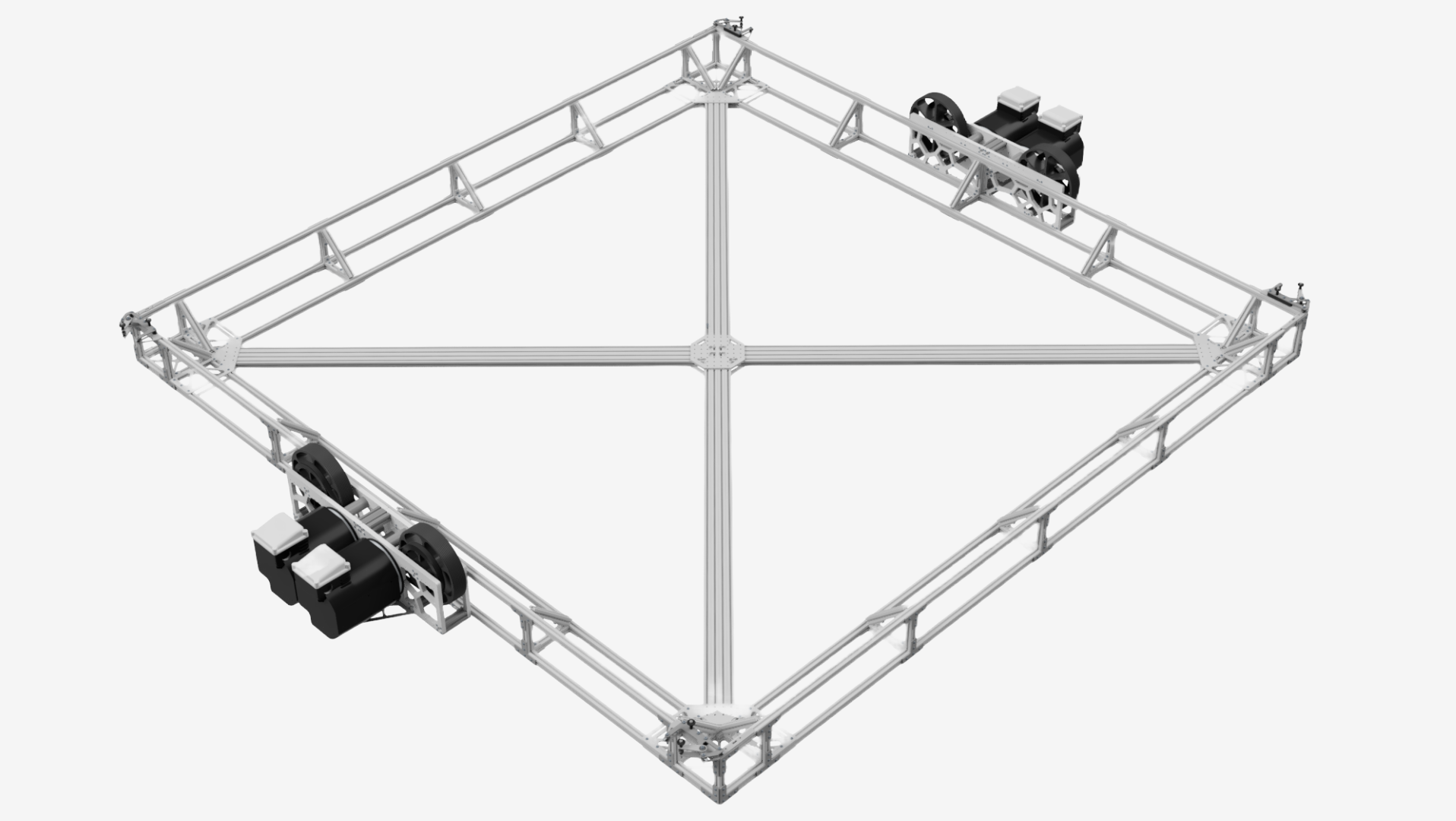

Initially, we considered a scissor lift platform, but it proved too heavy, bulky, and difficult to stow in overhead compartments. We then looked into pulley systems but found them potentially unstable and hazardous to seated passengers. Lastly, we explored ramps, but they were too steep and space-inefficient given the aisle height and narrow walkways.

Final Design

The final design requires five main steps to quickly and easily lift luggage into the overhead bin. To ensure accessibility, we focused on minimizing the weight of the motors and metal components. For portability, we created a foldable design that can be easily stowed away. Since this product is designed for those who have trouble lifting heavy luggage, we limited user interaction to simply pushing the luggage into the bin, which is built on a pivot.

Conclusion

This was my first time participating in a full day engineering design sprint. It was super fun working together in a small team under a time crunch because every moment felt productive. While there were moments where I believe we could have collaborated together more and assigned tasks better, it taught me the values of team management and assigning tasks that aligned with team members skill sets. Winning first place was a nice cherry on top!

Skills learned: Design sprint, Material and electronic spec sheets

Skills used: Solidworks, Fusion360, SCAMPER brainstorming