Introduction

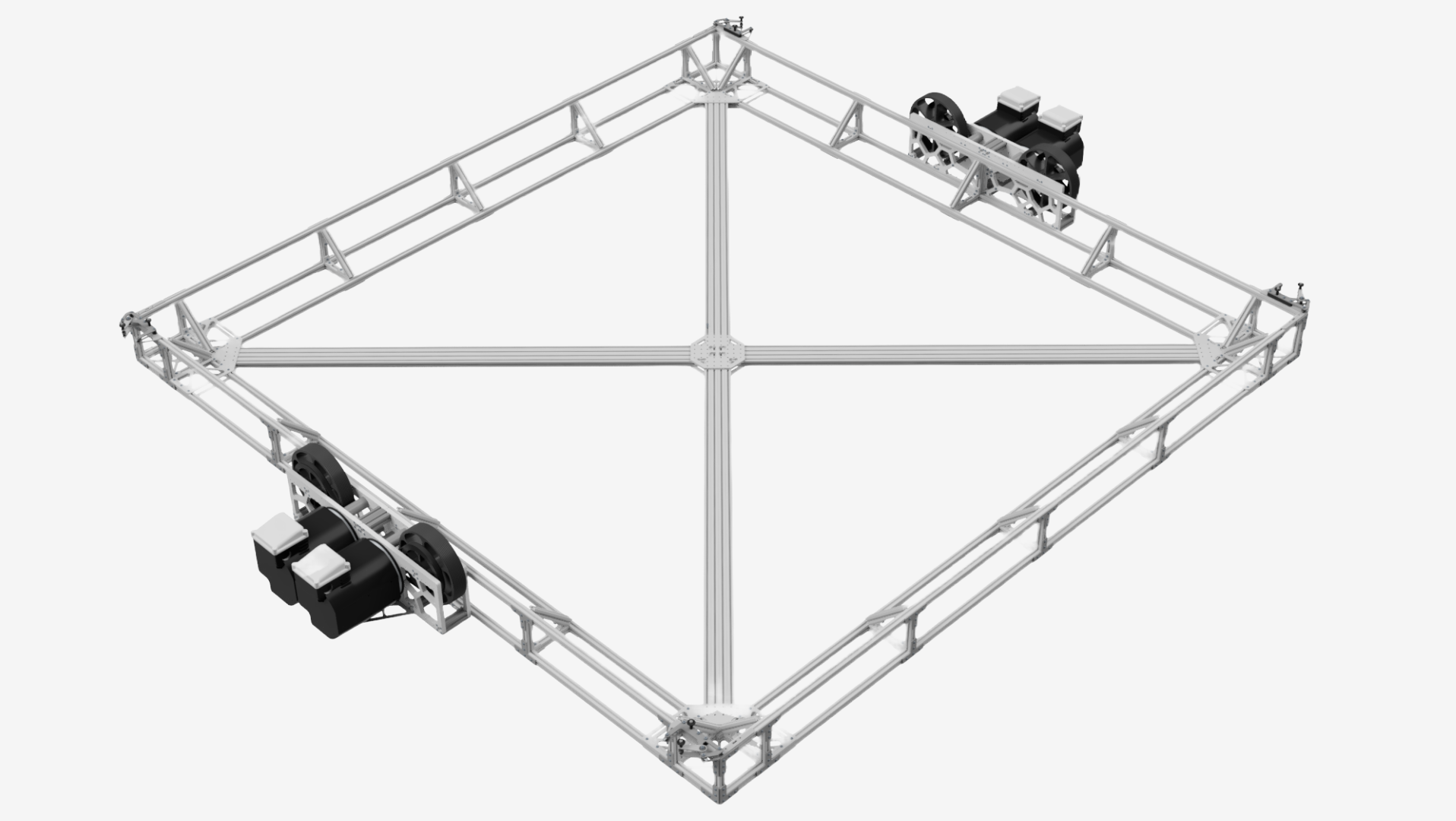

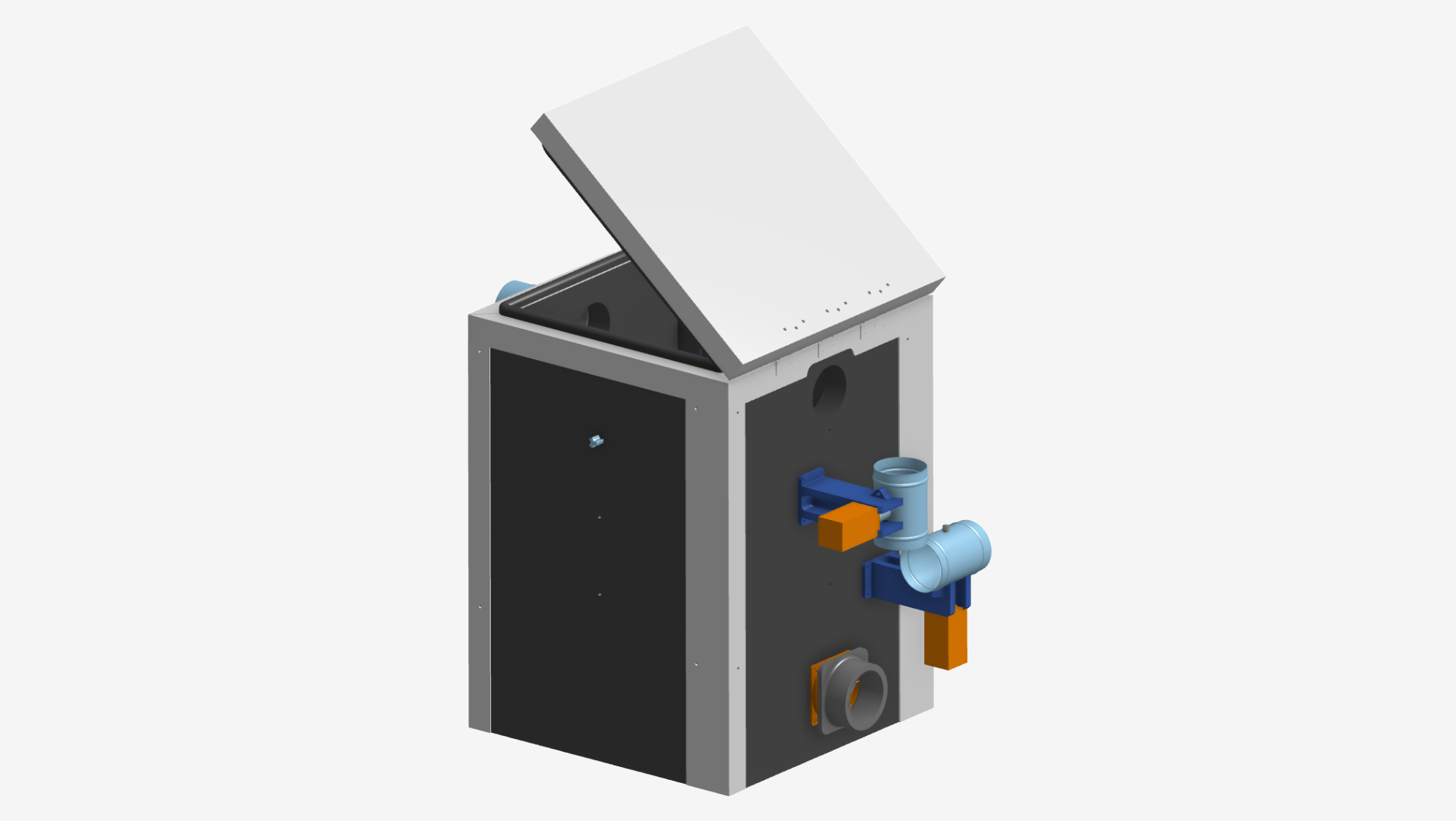

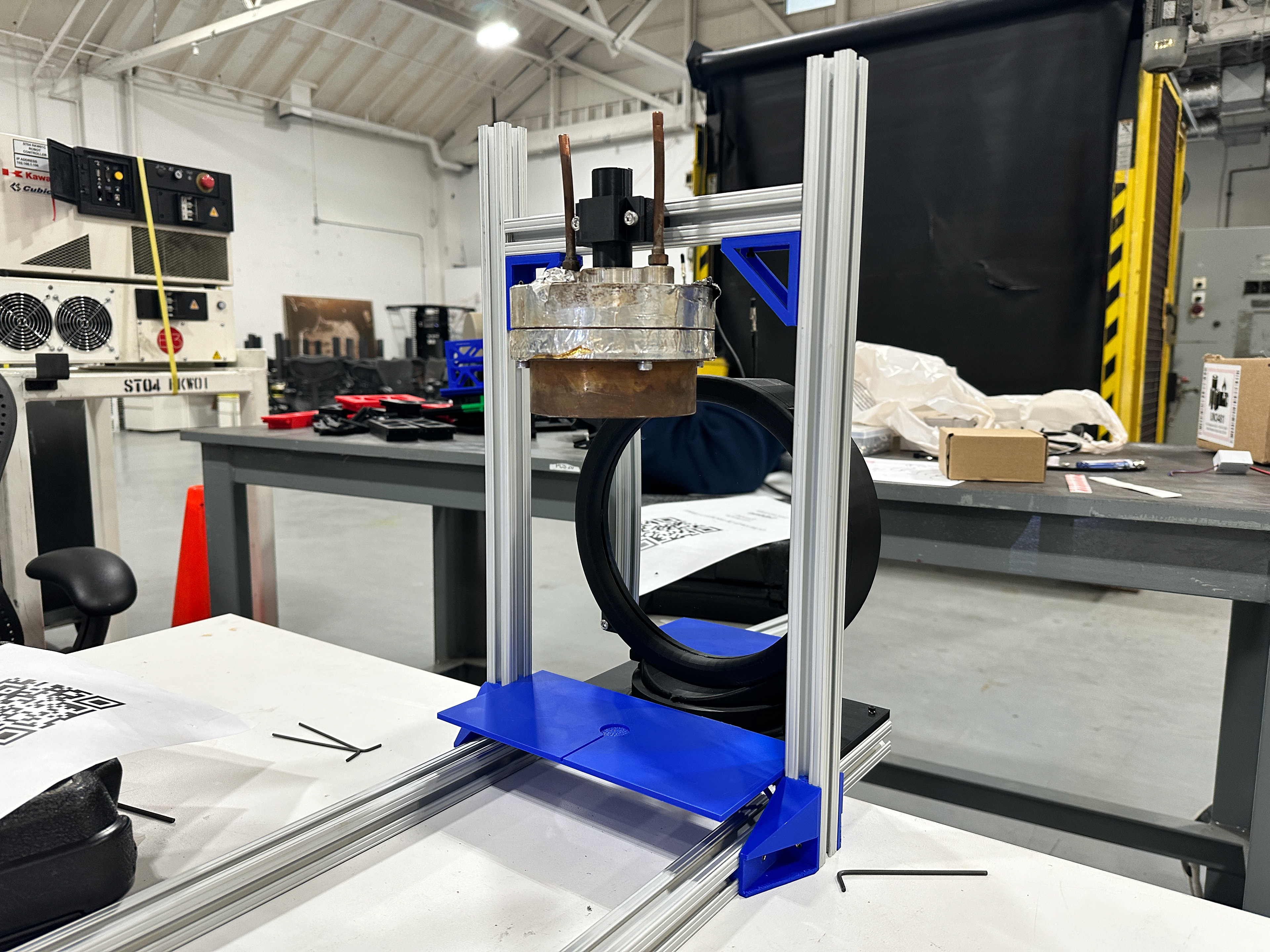

At Solideon, the team develops autonomous and deployable Wire Arc Additive Manufacturing (WAAM) systems compatible with a variety of robotic arms. Each system requires a shielding gas cup mounted at the welding torch end effector to deliver Argon and other cooling gas mixtures onto the weld zone, preventing oxidation and structural degradation due to environmental exposure. This schlieren imaging setup facilitates the visualization of these gas flows, enabling improvements in gas cup design aimed at optimizing flow rate, ensuring consistency, and minimizing overall gas consumption.

Requirements

- Large imaging area to effectively visualize gas cup

- Adjustable mounts for all parts for precise adjustments

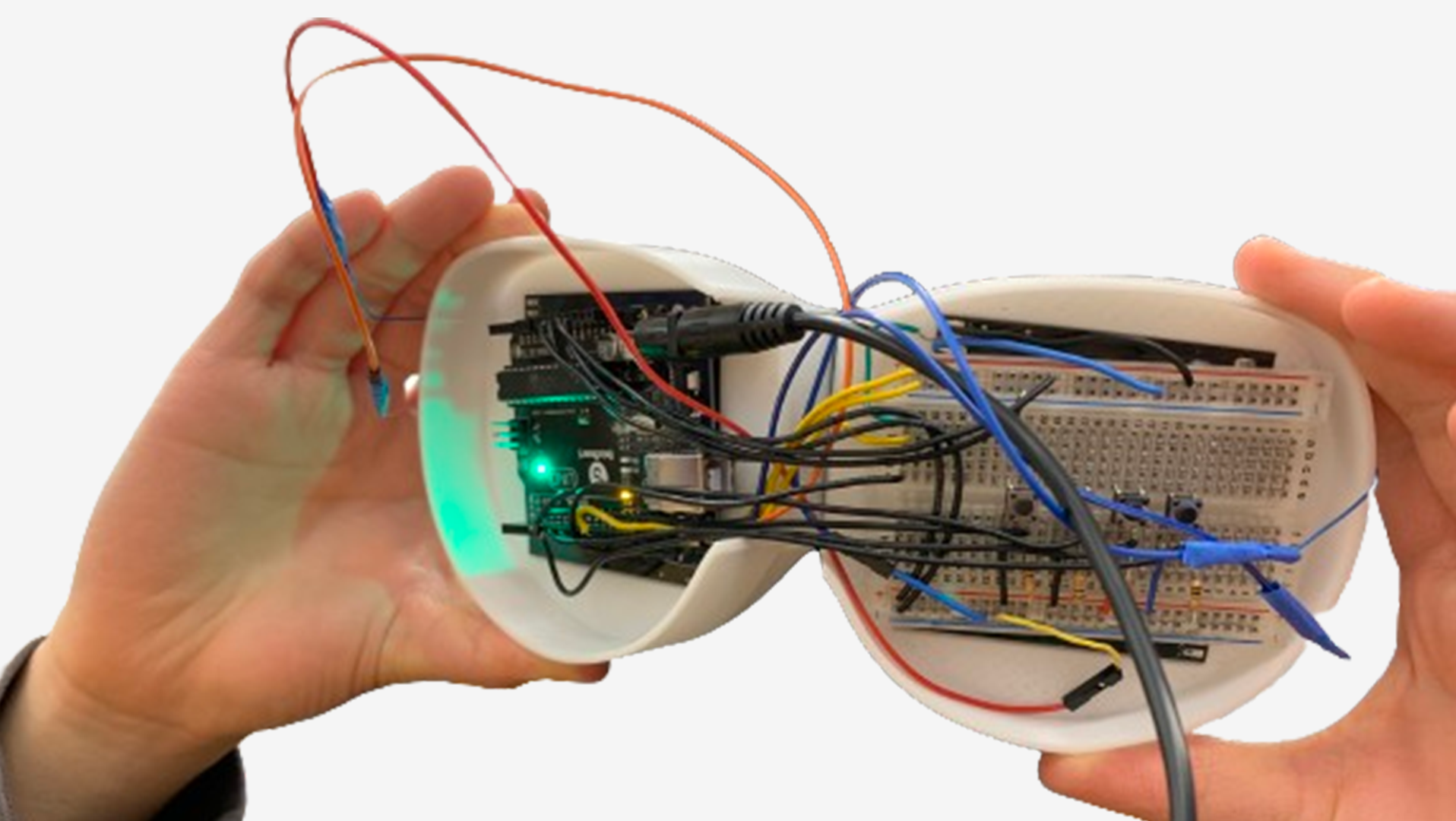

- Utilizes Basler pylon cameras

- Utilizes oxygen sensors for quantitative measurements

- Modular approach for easy assembly

- Budget of $2,500

Features

Conclusion

This was the first project that involved heavy research and testing before the final design. I thoroughly enjoyed learning about the science that makes schlieren photography possible and the different techniques and setups. Throughout this project, I constantly reiterated with 3d printed parts and implemented adjustable mechanism for easy and effective setups.

Skills learned: Methods to achieving laminar flow through a nozzle, techniques for adjustability

Skills used: Onshape, Solidworks FEA/CAD, Ansys CFD, Bandsaw, 3D printing